SPOC Automation Low Voltage vs Medium Voltage

The Challenge

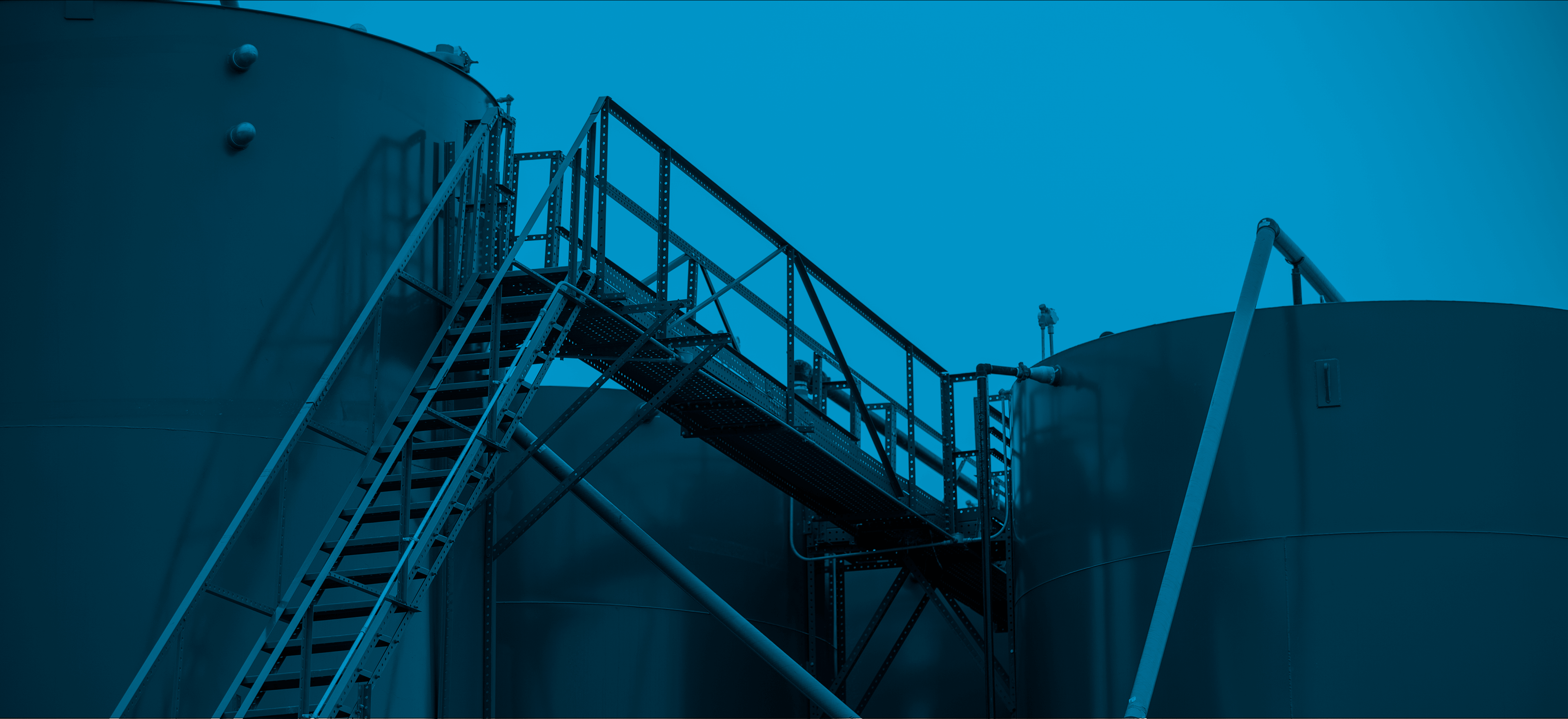

SPOC Automation manufactures control systems that run pumps in the oil and gas industry. They were routinely losing sales to a product that was far more expensive and far more dangerous for the people who must work on it.

Our challenge was to mathematically prove why using a 480V drive on motors less than 1000HP, instead of the traditional 4160V option, is a smarter choice.

There was a complication to this challenge — the oil & gas industry has a strong bias towards “what we’ve always done.” It’s an emotional hangup that makes changing behavior difficult.

Industry

Manufacturing and Technology

Conversion Point

Contemplation to Planning

Planning to Action

Solution

Our first task was to mathematically prove that SPOC’s 480v drive was the smarter choice. This wasn’t difficult because their drive is less expensive to buy and less expensive to operate; it saves money through huge gains in efficiency, but it’s also easier and cheaper to maintain over the life of the product.

Part of our strategy, though, was to move beyond the logic of the mathematical comparison. We also included a powerful emotional argument, showing how the SPOC product is far less dangerous to the crews who must work with it. (Consider that 4100 volts of electricity can arc across the room to kill even if you never touch the device!) As a consequence of the increased safety, it’s also far easier to find qualified experts capable of working on the technology.

For this project, we created a series of tools: a cost-savings analysis, training videos (both short and long form), as well as web content.

An example from the case study website:

Processes Used

Emotional Arousal and Rational Re-Evaluation

Results

Switching to a 480V from a 4160V can save a total of $152,132.00 for one pump over the course of 5-years.